Share to

From March 25 to 27, Shenkai will attend the CIPPE in Beijing to show comprehensive solutions for “deep-earth engineering” and integrated solutions for “directional well survey, logging and geosteering” in an all-round and systematic manner. We sincerely look forward to new and old customers to visit our stand!

By always upholding dual-engine driving of market-leading and innovation-leading and fully leveraging its technological advantages accumulated over thirty years in the field of petroleum equipment, Shenkai has made technological breakthroughs in key areas including well control equipment, remote control equipment, special rubber, wellhead equipment, comprehensive logging, digital logging, logging while drilling (LWD), etc., overcome a series of world-class challenges caused by deep wells, ultra-deep wells, and extra-deep wells, such as ultra-high pressure, ultra-high temperature, difficulty and long time in coring, and launched comprehensive solutions for “deep-earth engineering” to provide support for China’s deep and ultra-deep oil and gas exploration and development.

In 2023, Shenkai’s oil and gas equipment and various instruments stood out in multiple deep oil and gas development projects. In February 2023, Shenkai’s BOP control systems, comprehensive logging instruments, etc. facilitated the successful completion of the Southwest xx well of PetroChina, the “deepest vertical well in Asia”, with a depth of 9026m; In June 2023, Shenkai’s 140MPa BOP arrived at the Penglai gas field to assist the drilling company in dealing with the challenge of abnormal high pressure; In July 2023, Shenkai’s engineering team was in place at a well site in Tarim to provide logging services for the ultra-deep well with a design depth of 9213m; In September 2023, Shenkai’s TMWD system overcame adverse effects such as high temperature and high vibration in the Fuling block, and successfully completed MWD at a depth of 6842m; Shenkai’s high-temperature and high-pressure direct push logging system has been successfully applied in ultra-deep wells for multiple times, with a new entry depth of 9316m. In areas including Penglai, Fuman, Shunbei,etc., Shenkai workers are making contribution to China’s petroleum industry against the scorching heat and cold.

Introduction to the Solutions for Deep-earth Engineering

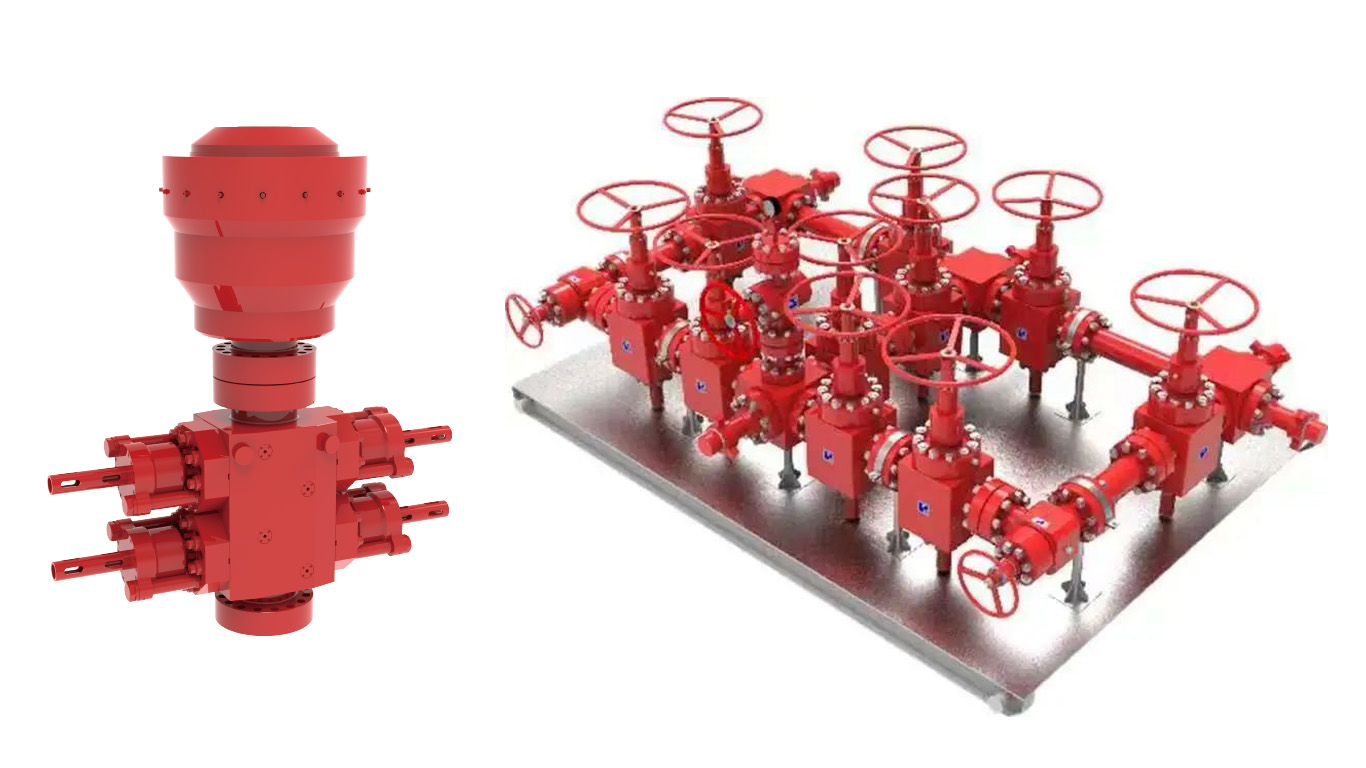

Solutions for ultra high pressure and high temperature well control

China’s onshore deep and ultra-deep wells are featured with complex geological conditions, high drilling safety risks, and long drilling cycles. In particular, ultra-high temperature, ultra-high pressure, multi-pressure system, hard formation, poor drillability, rich acid fluid and other problems coexist in Tarim Basin and Sichuan Basin. Safe, high-quality and efficient drilling is extremely challenging in the face of a series of world-class technical problems for deep well and ultra-deep well drilling and completion.

As a leading manufacturer of BOPs, control systems, and manifold systems in China, Shenkai can provide ultra-high pressure and high-temperature well control solutions for ultra-deep drilling.

· ltra-high pressure BOP stack and manifold system (140MPa)

· High temperature resistant ram rubber core (max. limit temperature 177 ℃)

· Intelligent and refined control system (electronic control type)

· Integrated wellbore liquid level monitoring system (timely detection and alarm of well leakage and overflow)

Ultra high pressure intelligent wellhead solutions

With the continuous breakthrough and success of deep and ultra-deep wells, there is an increasing demand for pressure resistance of wellhead equipment. The high pressure of over 20000 psi in 10000m deep wells poses severe challenges to the sealing structure design, processing technology, material selection,etc. of wellhead equipment.

Shenkai has profound technical reserves in wellhead equipment and has taken the lead in developing HH level Christmas trees in China. Currently, in the application of deep and ultra-deep wells, the R&D and design of ultra-high pressure valves and Christmas trees, etc. have been completed, and fast, safe, and efficient intelligent management can be achieved together with the intelligent wellhead system.

· Ultra-high pressure, ultra load-bearing capacity wellhead and Christmas tree (175/210MPa)

· Ultra-high pressure valve series (175/210MPa)

· Intelligent wellhead control system

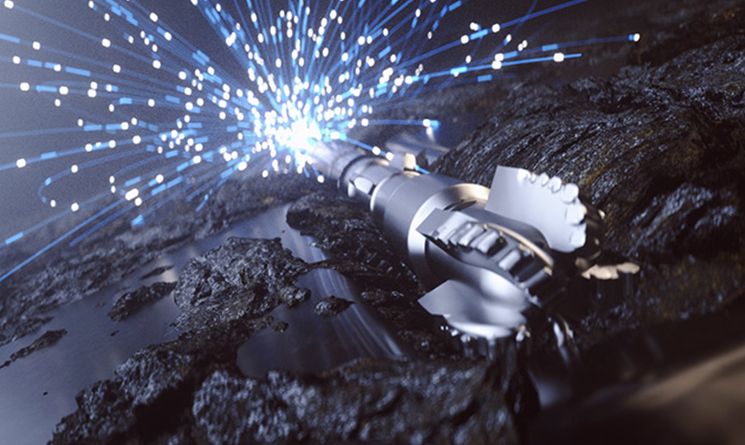

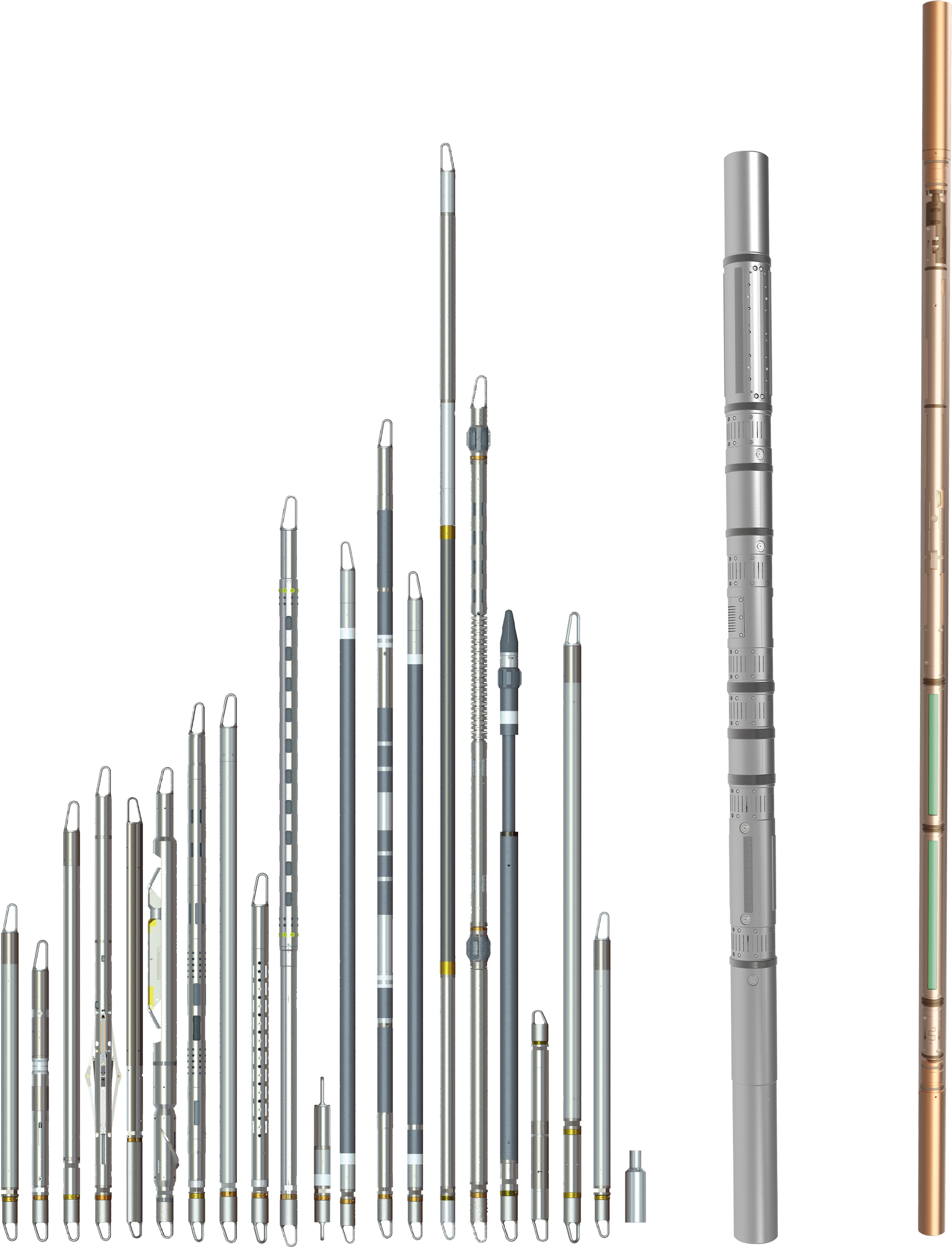

Solutions for ultra-high temperature and ultra-high pressure cable logging and LWD

Generally, there are difficulties in the exploration and development of deep and ultra-deep wells including ultra-high temperature and ultra-high pressure, and the downhole instruments has high requirements for temperature and pressure resistance; downhole instruments and tools are subjected to high vibration conditions far exceeding industry standards, which results in a significant increase in failure rate; due to the limitations of sealing design, some downhole instruments are facing severe challenges from high sulfur well conditions in the Southwest region.

With brilliant achievements in both in cable logging and LWD, Shenkai has overcome a series of difficulties such as high temperature resistance, high vibration resistance, high pressure resistance, and hydrogen sulfide resistance of downhole instruments, and provided high-quality downhole instruments and engineering technical services for major oil fields.

· PILS-X high-temperature, high-pressure, high-strength, large direct-push drilling plan (185 ℃/172MPa/20T)

· PILS85-X ultra high temperature, high pressure, high strength, small direct-push drilling plan (230℃/206MPa/20T)

· AziExpress? geodirectional LWD system (175 ℃)

· SK-TMWD Pro LWD system (185℃)

· SK-TMWD enhanced drilling parameters wireless LWD instrument

· High-temperature inclined sensor, ultra-high temperature insulation bottle, ultra-high temperature tensiometer and other core components

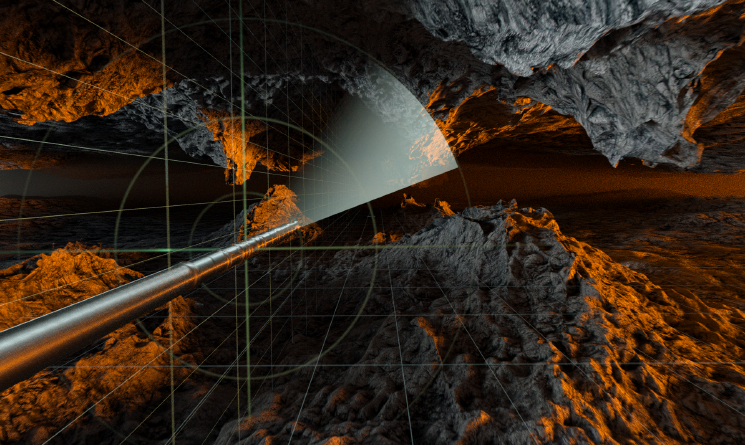

Comprehensive logging solutions for rapid oil and gas identification

The comprehensive logging technology is widely used in the drilling process of oil and gas exploration activities, which is mainly used in formation evaluation, oil and gas resources evaluation, monitoring drilling construction, etc. With the rapid development of computer technology, comprehensive logging is developing towards multi-source, multi-channel, and quantitative evaluation, and has become the core unit of wellsite data collection and processing.

Shenkai takes the lead in the field of comprehensive logging in China. It constantly makes technological innovation in logging services for high-temperature and deep wells, provides various effective solutions for the industry, and provides data service platforms for customers.

· Gas logging solutions for mixed oil drilling fluid under high background values

· High-temperature sensor for drilling fluid under ultra-deep well conditions (125 ℃)

· Onsite rapid identification and nuclear magnetic resonance analysis system for rock debris and cores

· Remote logging system and comprehensive logging system for well factories