Solutions for Hydraulic Locking of Ram BOP

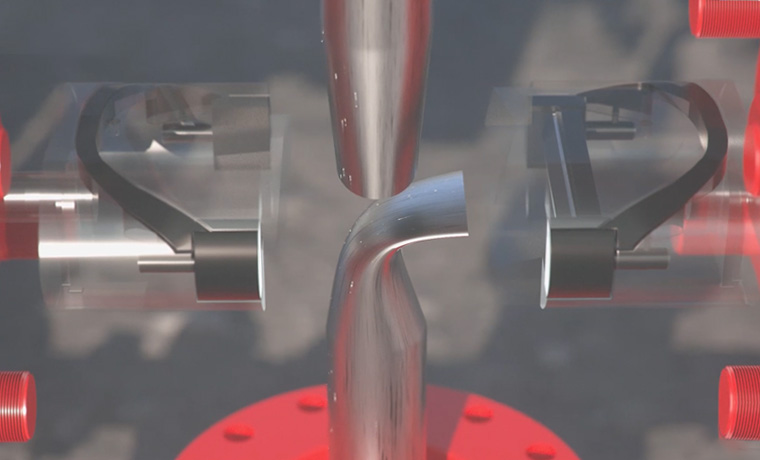

?The ram BOP locking mechanism is an important mechanism to ensure reliable ram closing and safe well shut-in, which is divided into manual operation locking mechanism and hydraulic automatic locking mechanism. Characterized by automatic ram locking and unlocking with no manual operation, low labor intensity and high efficiency, the hydraulic automatic locking mechanism is suitable for the situations with high automation requirements for BOP and limited installation space.

Solution Brief

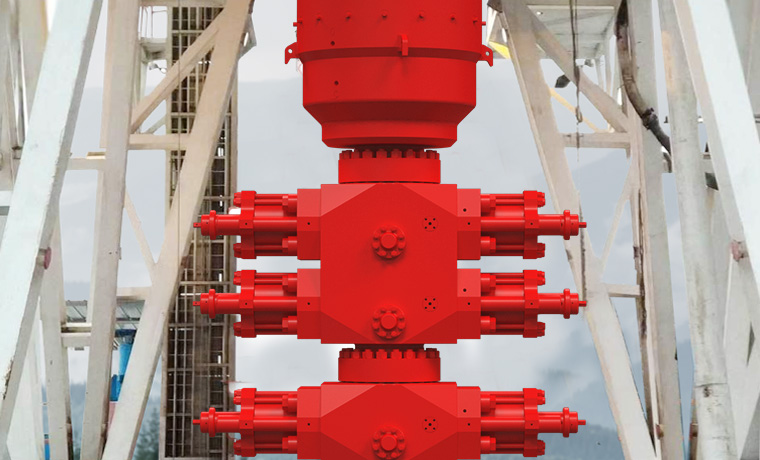

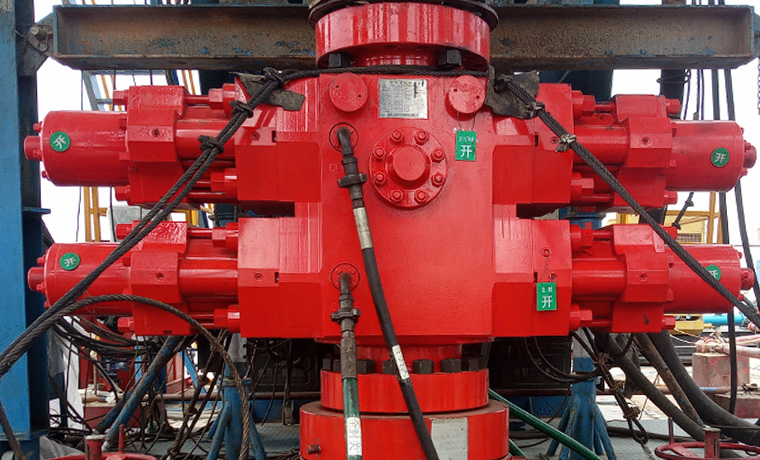

Shanghai Shenkai Petroleum Equipment Co., Ltd. can provide the hydraulic automatic locking mechanism (hydraulic locking mechanism) for ram BOP. This hydraulic locking mechanism is independently developed and designed by our company, which uses a set of hydraulic systems to achieve automatic ram locking and unlocking. It has obtained intellectual property patents and has been verified through fatigue test. This hydraulic automatic locking mechanism can meet the automatic locking requirements of the piston in different positions after the pipe ram (fixed hole ram), variable-diameter ram and shear ram are closed, that is, the main piston can achieve automatic locking within a large range of positions.

Bore size range

7 1/16" -26 3/4"(179mm - 680mm) ram BOP

Pressure range

Maximum working pressure

Temperature range

Maximum working temperature

Performance level

PR1、PR2

Products

Related Solutions

Company

Shanghai Shenkai Petroleum Equipment Co., Ltd.

Shanghai Shenkai Petroleum Equipment Co., Ltd., a wholly-owned subsidiary of Shenkai Enterprise, is a high-tech company specializing in the research, development, and manufacturing of oil drilling and well control equipment, as well as oil recovery wellhead equipment. The company focuses on the research, development, manufacturing, and sales of drilling blowout preventers, throttle pressure well manifolds, wellhead oil (gas) recovery trees and their control systems. With a complete production management and quality assurance system, the company has passed the QHSE system certification and has obtained the API licenses for APIQ1, 6A, 16A, 16C, 16D, and 17D for over 20 years. In addition, the blowout preventers and control systems developed and produced by the company have both received PetroChina's Class A qualification.